Analyzing Moisture Sensitive/Reactive Gases

Home - Analyzing Moisture Sensitive/Reactive Gases

Direct Analysis for Reactive Gases: Trace Metals Solved

Reliable Trace Metal Quantification in Reactive & Moisture-Sensitive Gases

Proprietary Methods and Apparatus (Patent US20240272122A1) for Direct Analysis, Ensuring Ultra-High Purity Compliance Where Traditional Impingers Fail.

Secure your semiconductor fabrication line by gaining robust, accurate, and direct measurement of trace metal contamination in critical process gases without the risk of hydrolysis or sample degradation.

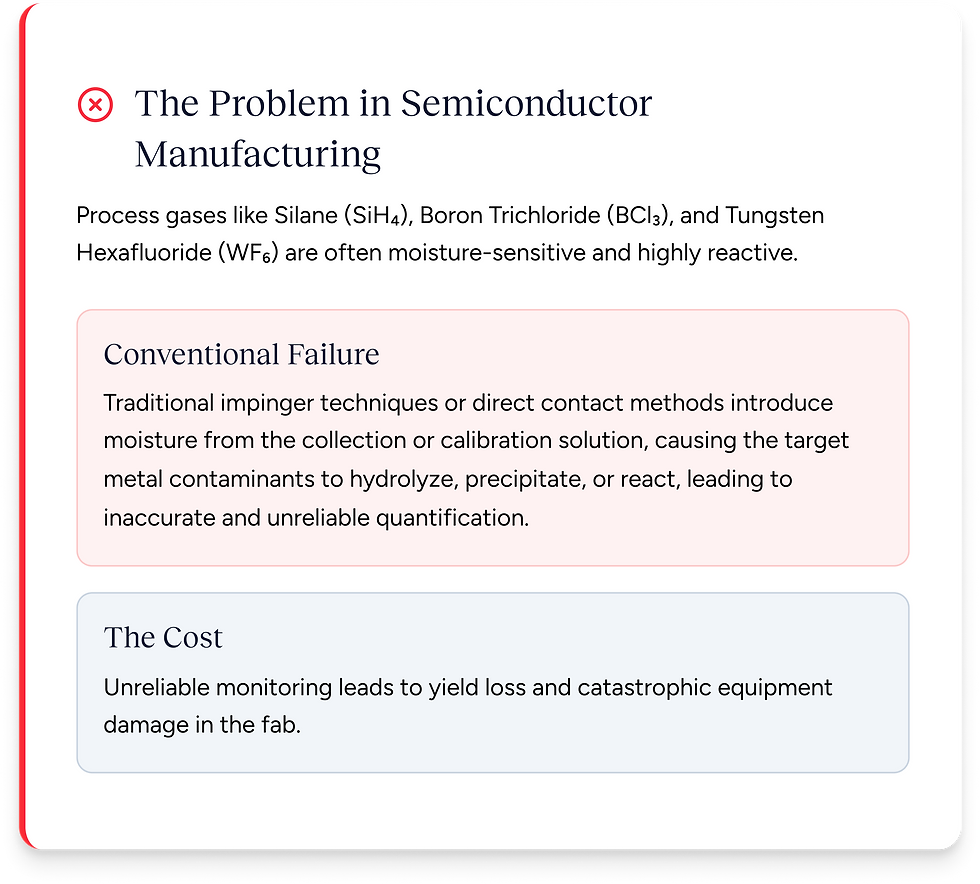

The Purity Challenge

Sample Preparation Failure

High-stakes problems in semiconductor manufacturing that require unique solutions

The Technology

Dual Exchange for Robust Analysis

The mechanism that enables success in these difficult matrices

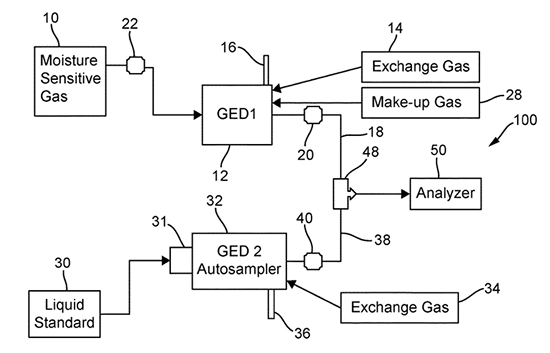

Patented Dual Gas Exchange Device

The core of the invention is a two-step system designed to handle both the reactive sample and the calibration reference safely:

Stage 1

Sample Exchange

The initial device facilitates the transfer of metal contaminants from the moisture-sensitive sample gas into a carrier solution without allowing the gas itself to contact the solution's water content.

Stage 2

Sample Exchange

A second, connected gas exchange device is utilized to introduce moisture-free, controlled metal spikes from the calibrant solution, ensuring that the calibration process itself is not compromised by the reactive gas's presence or by external moisture.

Advanced Ionization & Detection

The system integrates a precision ionization source with an advanced detection device, ensuring accurate measurement of trace metal contaminants.

1

Light Source & Ionization

Controlled ionization of sample introduction for precise analysis

2

Sample Introduction Device

Integrated sample handling without moisture contamination

3

Detection Device

High-sensitivity detection for ppb-ppt level quantification

Patent diagram showing the integrated ionization and detection system configuration

Result

Direct & Interference-Free Analysis

This method achieves the required transfer efficiency and matrix se paration, enabling a robust analysis of the resulting solution via standard ICP-MS or ICP-OES techniques.

Analysis Method

ICP-MS / ICP-OES

Detection Level

ppb - ppt

The Purity Challenge

Ensuring Process Integrity

The primary focus is compliance and quality control in ultra-pure environments.

01

Semiconductor Process Gas Qualification

Benefit:

Provides the required ultra-trace metal certification (e.g., ppb or ppt levels) for all specialty gases entering the fab, including challenging hydrides and halides.

02

Chemical Manufacturing Quality Control

Benefit:

Enables direct, on-site quality control for manufacturers of high-purity chemicals, reducing reliance on slow and failure-prone external lab analysis.

03

Regulatory and Safety Compliance

Benefit:

Offers a standardized, validated method for monitoring potentially hazardous metal contaminants in reactive gases, improving worker safety and regulatory adherence.

Secure Your Purity Pipeline

The primary focus is compliance and quality control in ultra-pure environments.

Contact Us

Navigate critical Laboratory bottlenecks related to technology, talent, and compliance.

We’re here to guide you through laboratory challenges

with confidence and care. Let's Talk